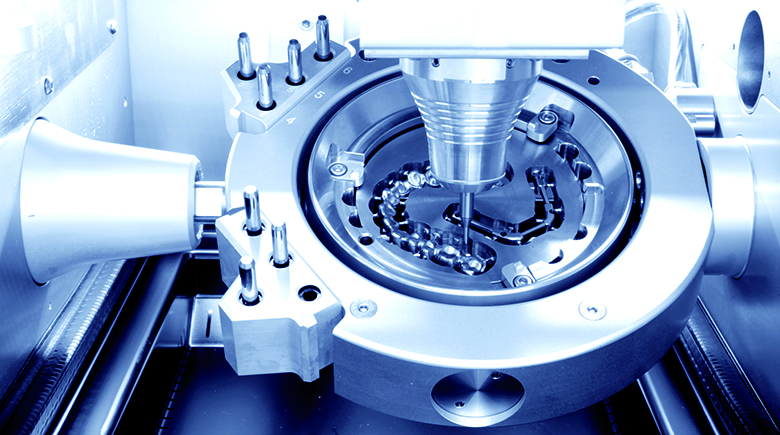

Фрезерный аппарат M1 Wet Heavy Metal

| With its orbit built on four bearings and the integrated wet processing function, the M1 Wet Heavy Metal milling unit is ideal for the milling of hard metals such as titanium. |

|

Equipment

- Computer-controlled 5+1 axes simultaneous milling unit with 8-fold tool changer, wet and metal processing (e.g. titanium and cobalt chrome)

- PC and screen

- CAM software

- Basic design software Zirkonzahn.Modellier

Overview of the characteristics

- 5+1 axes simultaneous milling with fourfold orbit

- Milling Spindle Hard Automatic with 8-fold tool changer

- Wet processing

- Support for precast titanium abutment blanks Raw-Abutment®

- Particularly space-saving

- Equipped with blocking air

Accessories

|

Ioniser M1 Device for the electrostatic discharge of plastic shavings for more cleanliness during the milling process (optionally for the new device or as retrofitting article) товарный номер: ZBAC3311 |

|

|

Raw-Abutment® Holder Holder for fixing and for the serial processing of up to three prefabricated titanium abutment blanks (Raw-Abutments®) in the Zirkonzahn milling unit with ⌀ 95 mm orbit товарный номер: ZBAC1691 |

|

|

Glass Ceramics Holder Holder for fixing and for the serial processing of up to four glass ceramic blanks in the Zirkonzahn milling unit with ⌀ 95 mm orbit товарный номер: ZBAC1651 |

|

|

JawPositioner Support Support used to fix the JawPositioner into the ⌀ 95 mm orbit of the Zirkonzahn milling unit товарный номер: ZBAC3511 |

Processable materials with full equipment

|